Vacuum homogenizing emulsifier

Mixing Type

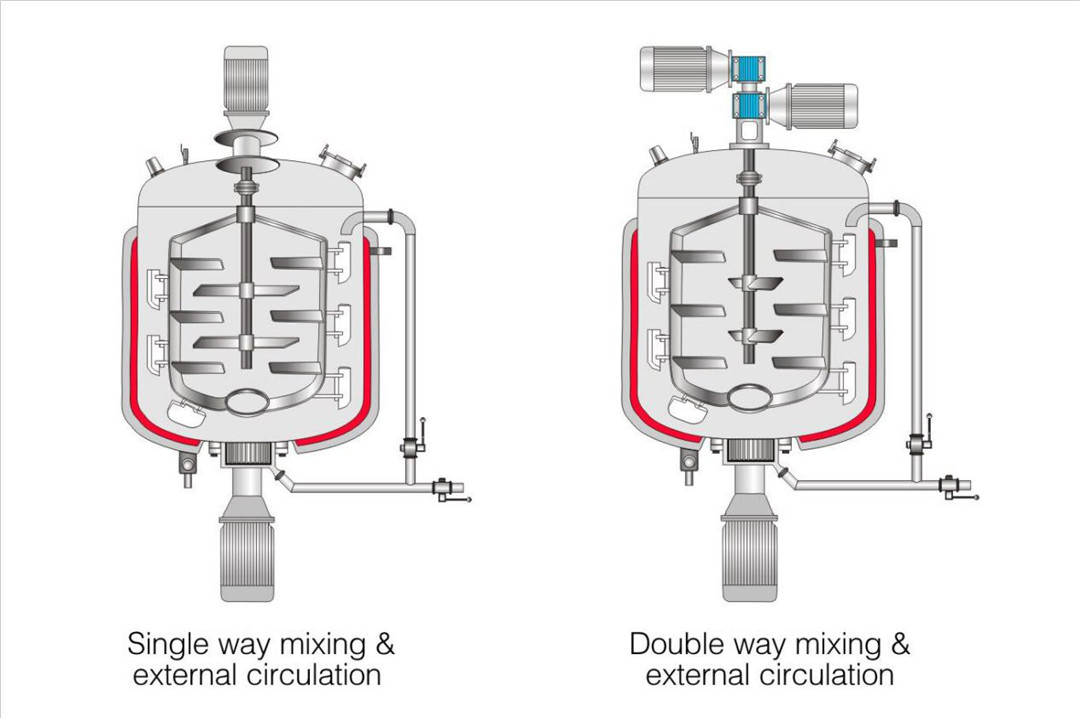

Single stirring external circulation: It is composed of the main paddle and the auxiliary paddle. The clockwise rotation of the main paddle can quickly and uniformly mix the raw materials. The auxiliary paddle can disrupt the vortex so that the product mixes smoothly. When the production of the product is completed, the product can be transported to the top of the pot again through the external circulation, and stirred and homogenized again to further improve the quality of the product.

Double stirring external circulation: It is composed of two main paddles, which rotate rapidly clockwise and counterclockwise respectively. Adjusting the speed of the paddle through the frequency converter can dissolve the mixed raw materials more efficiently and quickly, and can immediately prevent the materials from sticking to the inner wall of the pot to avoid caking. It can also be returned to the pot through the pipeline for further circulation stirring and emulsification.

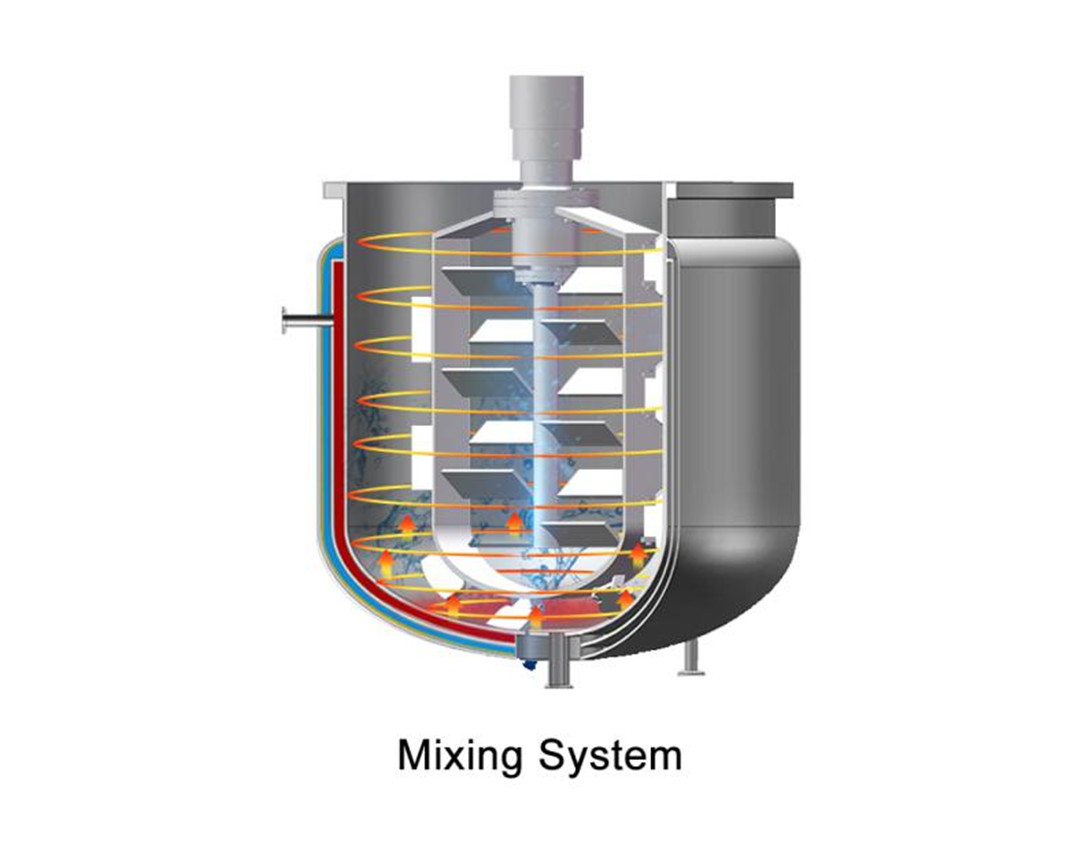

The 3D container anatomy diagram clearly describes the structure of the whole pot and the operation of materials:

Mixing system: One-way stirring, two-way stirring, two-way stirring with spiral belt, one-way stirring with spiral belt, anchor stirring and other frequency conversion speed regulation, 0-63r/min, The Teflon scraper can meet the shape of the stirring tank at any time and scrape off the sticky material on the pot wall.