Vacuum homogenizer cosmetic cream making machine

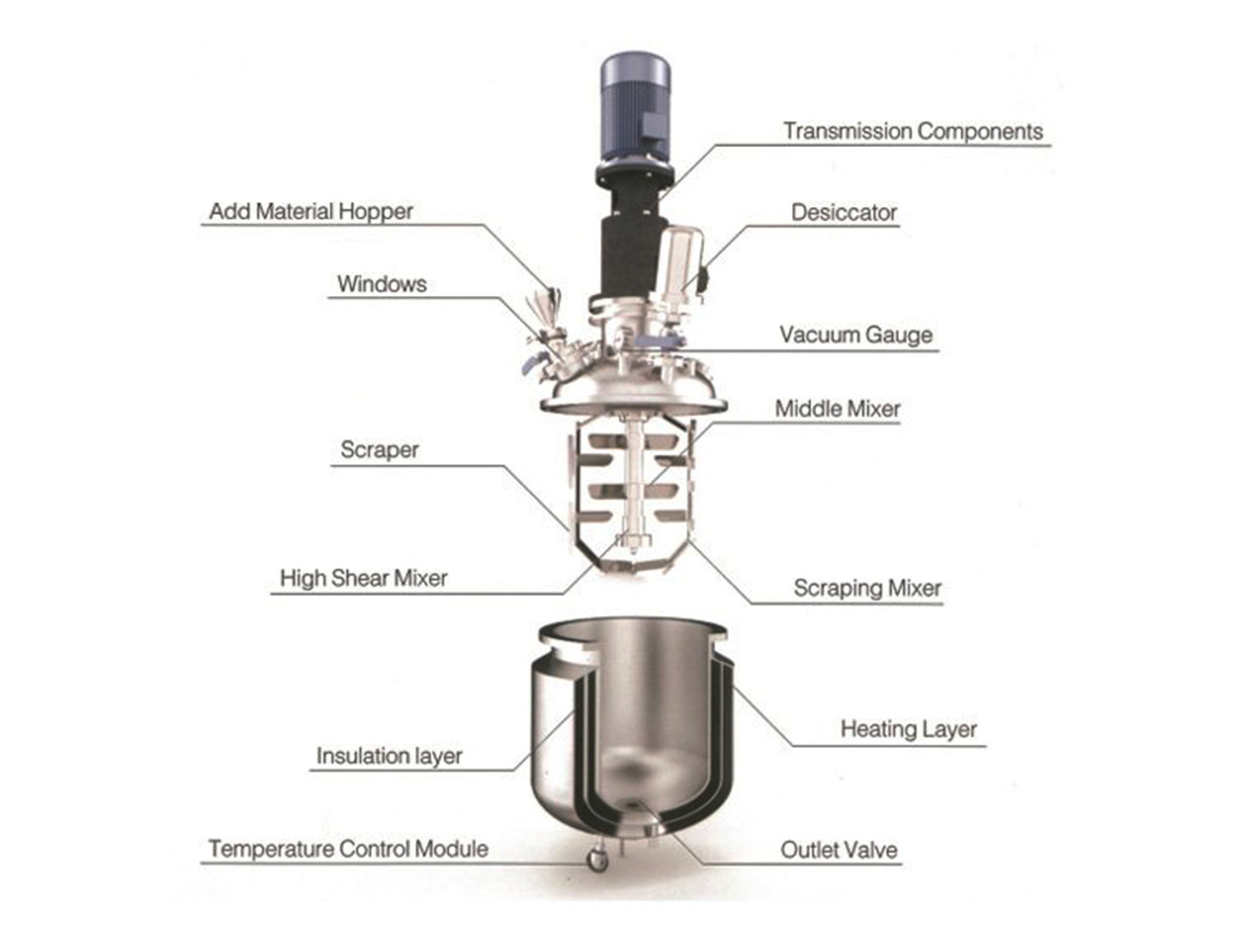

Main pot body diagram

Overall structure of the vacuum homogenizing emulsified:

Feature

● Contra-rotating slow mixing with teflon scrapers

● Control Panel T&S color kind to show all the main machine.

● Hydraulic lifting of the cover

● Hydraulic vessel tilting to facilitate the finished product discharge

● Essences little hopper

● Central bottom valves to suck under vacuum raw material or discharge the finished product

● Inspection window with light to check the mixing phases

Future

● Vessel clear by spray ball or CIP system

● Mixing with counter-rotating blade system and PTFE scraper

● Vessel lid and vessel tilting by Hydraulic system

● Visually monitor the production situation in the pot by glass manhole and mirror light

● Raw materials pretreatment by oil and water vessel

● Essences little hopper and powder hopper

● Complete pipeline GMP standard system

Parameter

| Capacity | Homogenizer Motor(KW) | Stirring motor(KW) | Vacuum pump(KW) | water pot stirring(KW) | oil pot stirring(KW) | water pot heating(KW) | oil pot heating(KW) |

| 250L | 5.5 | 2.2 | 1.5 | 0.55 | 0.55 | 12 | 9 |

| 300L | 5.5 | 3 | 3 | 0.75 | 0.75 | 18 | 9 |

| 400L | 7.5 | 4 | 3 | 0.75 | 0.75 | 18 | 9 |

| 500L | 11 | 4 | 3 | 1.1 | 1.1 | 18 | 9 |

| 1000L | 15 | 5.5 | 3.85 | 1.5 | 1.5 | 27 | 18 |

| 2000L | 18.5 | 7.5 | 3.85 | 2.2 | 2.2 | 36 | 27 |

| 3000L | 22 | 11 | 11 | 3 | 3 | ||

| 5000L | 37.5 | 15 | 11 | 5.5 | 5.5 |

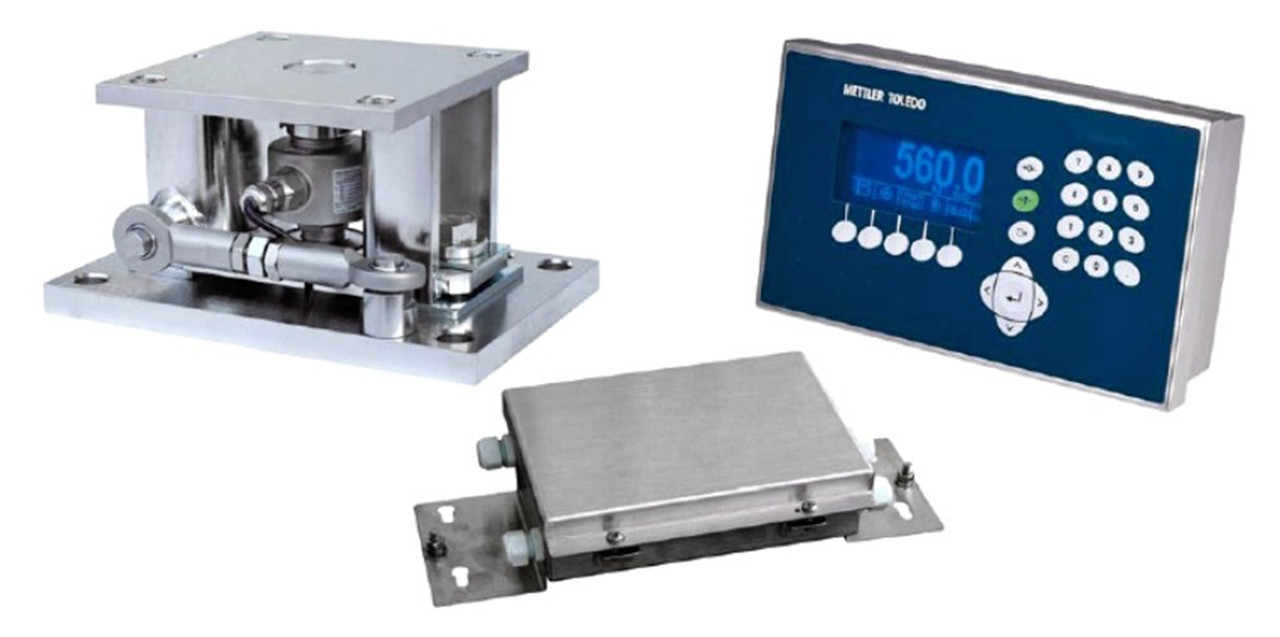

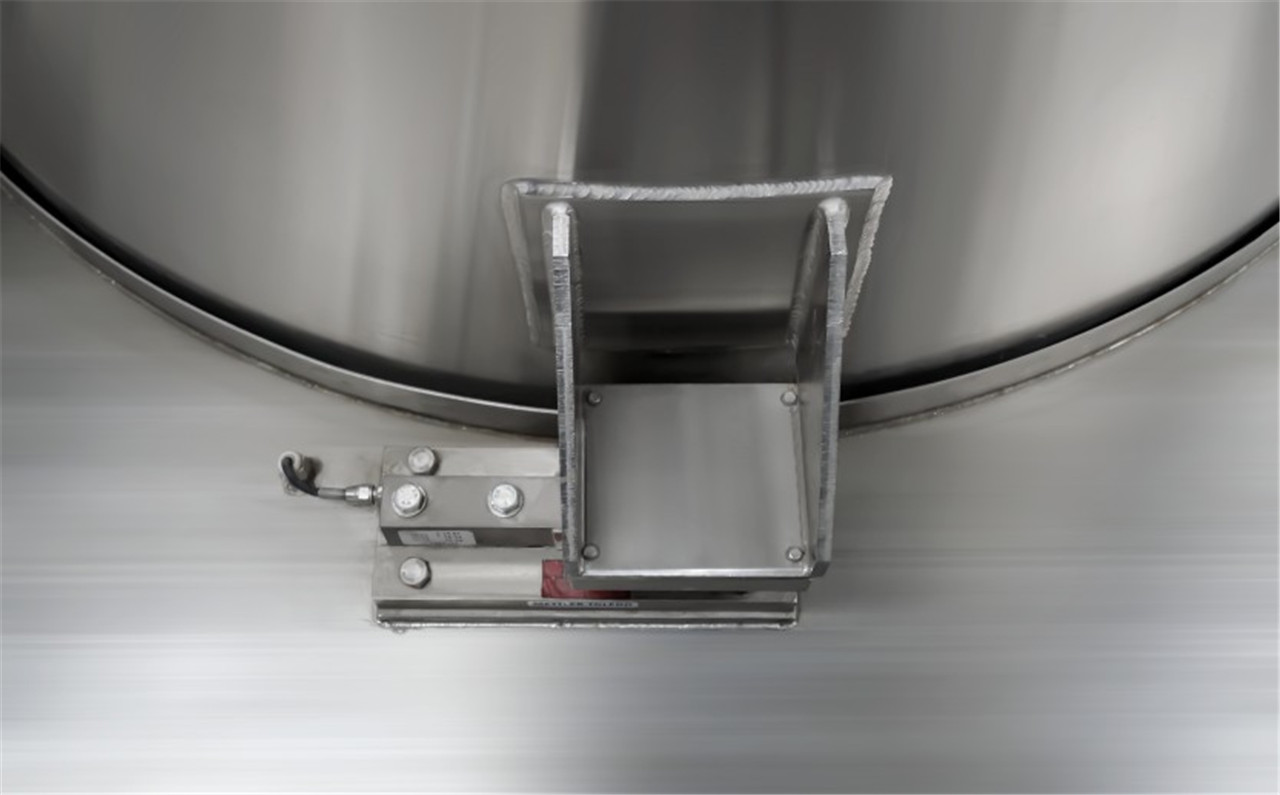

The structure of this emulsifying machine is mainly aimed at large-capacity emulsifying machines, industrialized production, and can be used in combination with multiple emulsifying machines. The combined emulsifying machine can be equipped with a waterproof operating platform of SUS304 material, as well as guardrail stairs and material lifting systems, weighing systems, and PLC remote control systems. Compared with traditional production, this automated production system can minimize labor and has high production efficiency.

Combined Type

Combined Type hydraulic lift emulsifier mixer:

Weighing System

Remote control system