Vacuum emulsifier lotion homogenizer mixer

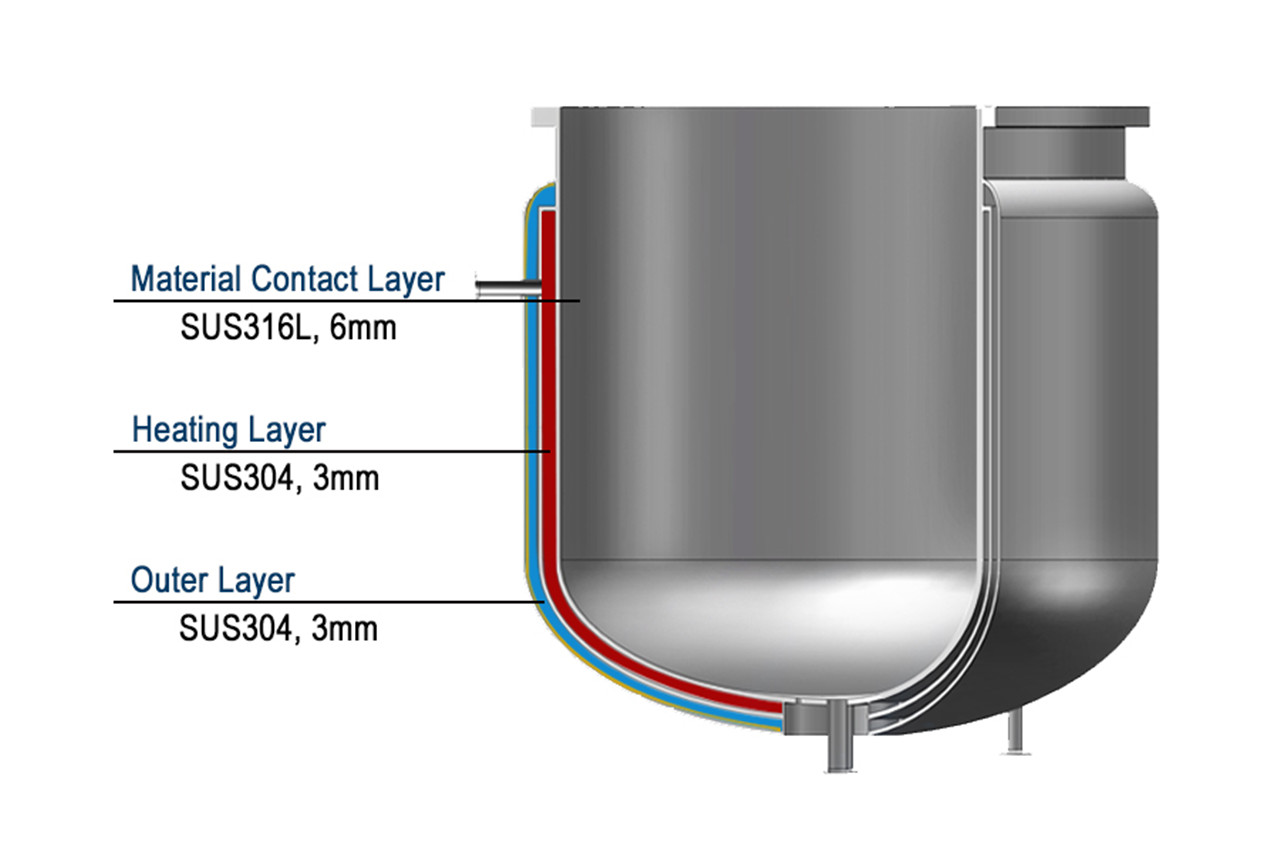

Main pot body diagram

Remark: The material of the pot body is determined according to the selected machine capacity.

Parameter

|

Capacity |

Homogenizer Motor(KW) |

Stirring motor(KW) |

Vacuum pump(KW) |

water pot stirring(KW) |

oil pot stirring(KW) |

water pot heating(KW) |

oil pot heating(KW) |

|

15L |

0.75 |

0.37 |

0.18 |

0.18 |

0.18 |

2 |

2 |

|

25L |

1.1 |

0.37 |

0.18 |

0.18 |

0.18 |

2 |

3 |

|

50L |

2.2 |

0.75 |

0.81 |

0.55 |

0.55 |

6 |

3 |

|

100L |

4 |

1.5 |

0.81 |

0.55 |

0.55 |

9 |

6 |

|

150L |

4 |

2.2 |

1.5 |

0.55 |

0.55 |

12 |

6 |

|

200L |

5.5 |

3 |

1.5 |

0.55 |

0.55 |

12 |

9 |

Future

● Vessel clear by spray ball or CIP system

● Mixing with counter-rotating blade system and PTFE scraper

● Vessel lid and vessel tilting by Hydraulic system

● Visually monitor the production situation in the pot by glass manhole and mirror light

● Raw materials pretreatment by oil and water vessel

● Essences little hopper and powder hopper

● Complete pipeline GMP standard system

Application Fields

● Daily chemical products: cosmetics, creams, lotions, facial masks, cleaning products, toothpaste.

● Custom designs are available according to production requirements.

● Pharmaceutical industry: pharmaceutical ointment, gel, suspension, capsule, oral liquid, nutrient solution etc...

● It can be customized according to the production or research and development requirements of the pharmaceutical industry.

● Food industry: mayonnaise, salad dressing, chocolate sauce and other pastry sauces, food additives, beverages, jams, butter, pet food.

● Chemicals: detergents, polishes, lubricants, preservatives, dyes, solvents, rubber, resins, shoe polish and other general chemicals.

● New materials: graphene, lithium battery slurry, polymer composite materials, electronic chemical materials, ultra-pure and ultra-fine inorganic materials.