-

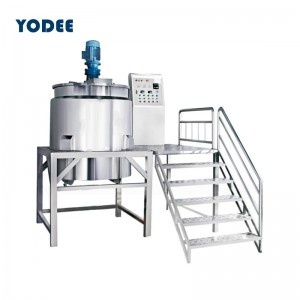

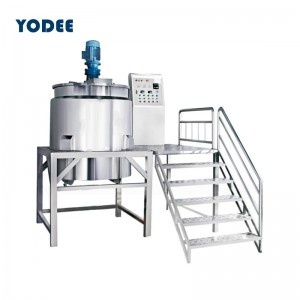

Vacuum homogenizing emulsifier

The YODEE fixed type emulsifier is the most economical in the series of emulsifiers. The difference from the hydraulic lift emulsifier is that the top cover cannot be opened, and the top cover and the pot body are made in one piece. But there are also the same configuration as the water-phase pot, oil-phase pot, emulsification and stirring main pot, vacuum system, electrical control system, and operation platform of the lifting emulsifier. Optional systems: batching system, discharging system, cooling and heating temperature control system, vacuum system, PH value online measurement control, CIP and SIP cleaning system, etc.

-

Automatic Perfume Making Machine With Freezing Chiller Filter Mixing

Freezing Filtration Equipment mixes, alcoholizes, stabilizes, clarifies, and filters the liquid at normal pressure and low temperature. Chiller Filter Mixing Machinery can be used for the production of perfume, toilet water, mouthwash, etc. It can also be used for clarification and sterilization filtration of small amounts of liquids, or micro chemical analysis in scientific research departments, hospitals, laboratories, etc.

The material is made of 316L stainless steel, pressure source is a pneumatic diaphragm pump imported from the USA for positive pressure filtration. The connecting pipeline adopts sanitary grade polished pipe fittings and quick-install connection method, Easy to assemble and clean.

-

Heated stainless steel liquid mixing tanks with agitator

Liquid washing mixing tank is designed and developed independently by YODEE. It is mainly suitable for liquid detergent, detergent, shampoo, shower gel, hand sanitizer and other products. It integrates stirring, homogenization, heating, cooling, pump discharge, defoaming ( Optional type) and other functions are integrated, it is an ideal equipment for manufacturers at home and abroad to configure washing products.

-

Industrial chemical / cosmetic / dairy / jacketed mixing tank with stirrer

Large-scale production is very common in daily chemical series products, and batch-type stirring vessels are set up, and the integrated fully automatic intelligent production system can improve output and product quality. While optimizing the factory structure, it can save a lot of labor and help companies control operating costs.

-

liquid hand wash / dishwashing / detergent mixer making machine

The liquid washing mixing pot is mainly composed of mixing pot, electrical control system, working platform and other parts.The machine stirs at a slow speed through the paddles in the pot, so that the materials are fully mixed and blended to meet the requirements of the customer’s production process.

Mixing machine is mainly suitable for liquid detergent products, such as washing machine cleaning agent, laundry liquid, detergent, etc.The mixing tank integrates the functions of mixing and discharging, with strong production capacity, convenient cleaning and low production cost. It is the first choice for detergent factories.

-

liquid soap / shampoo mixing vessel double jacketed reactor with agitator

The liquid washing homogenizing Mixing Machine is mainly suitable for the mixing and stirring of different materials, the mutual mixing, dissolving and uniform mixing of mucus, etc. It is an indispensable equipment in various industries.

It integrates the functions of frequency conversion speed regulation scraping wall stirring, high shear homogeneous emulsification, heating, cooling, electric control, temperature control, operation platform and other functions. It is an ideal equipment for domestic and foreign manufacturers to configure materials.

-

Automatic position double side labeling machine for flat round bottle

YODEE automatic double-sided labeling machine is suitable for single-sided and double-sided labeling of flat bottles, round bottles and square bottles, such as shampoo flat bottles, lubricating oil flat bottles, hand sanitizer round bottles, etc.

The machine can label both sides of the bottle at the same time to improve production efficiency, and is widely used in daily chemical, cosmetic, petrochemical, pharmaceutical and other industries.

-

Automatic round bottle labeling machine for single double label

YODEE automatic positioning round bottle labeling machine is suitable for labeling the circumference of cylindrical objects, and can be single-label and double-label. The distance between the front and back double labels can be adjusted flexibly, such as labeling of gel water bottles, food cans, etc., which are widely used in cosmetics, food, medicine, disinfectant water and other industries.

The labeling machine can be equipped with a circumferential positioning detection device, which can realize labeling at a designated position on the circumferential surface. At the same time, the color matching tape coding machine and the ink jet coding machine can be selected to realize the printing of the production date and batch number information on the label, and the integration of labeling and coding.

-

30ml semi automatic vertical volumetric liquid paste filling machine

The semi-automatic paste filling machine is mainly for products with medium to high viscosity. The machine has two types: single head paste filling machine and double head paste filling machine.

The vertical filling machine uses the three-way principle that the cylinder drives the piston and the rotary valve to extract and eject high-concentration materials, and controls the stroke of the cylinder with a magnetic reed switch to adjust the filling volume.

It is widely used in medicine, daily chemical, food, pesticide and special industries. The whole machine is made of food-grade SUS304 material, which has the characteristics of corrosion resistance and wear resistance.

-

Semi auto pneumatic single head horizontal liquid filling machine

The horizontal filling machine is completely controlled by compressed air. No power supply is required, especially suitable for explosion-proof environments, production workshops with high safety, and in line with the requirements of modern enterprises.

Due to the pneumatic control and pneumatic special three-way positioning, it has high filling accuracy, simple operation and low failure rate. It is an ideal filling machine for quantitative filling of high-concentration fluids and pastes. Mainly used in medicine, daily chemical, food, pesticide and special industries.

-

Constant temperature hot wax heating mixing filling machine

The vertical water circulation constant temperature filling machine is equipped with heating and temperature control device and agitator. It adopts water circulation compartment heating and full pneumatic quantitative filling. This filling machine is mainly for paste materials with high viscosity, easy to solidify and poor fluidity.

-

High speed automatic single head liquid jar filling machine

With the continuous changes in the market, the cost of raw materials and labor is constantly rising. Both small-scale or large-scale manufacturers want to find a filling machine that can meet the needs of a large variety of products in the factory. Compared with the generall automatic filling machine, this filling machine can fill a variety of products in different media, such as cream, lotion, and liquid etc. It can meet the requirements of low price while increasing the output.