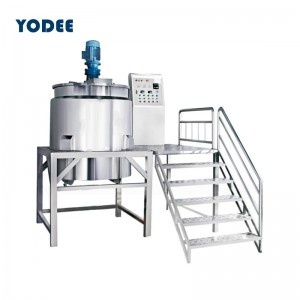

liquid soap / shampoo mixing vessel double jacketed reactor with agitator

Function

● Reducer: reduce speed, increase torque

● Blocking slurry: prevent the material from rising up during stirring

● Wall scraping mixing: Optional, slurry/anchor/frame/ribbon type

● Temperature Probe: Detects temperature

● Insulation layer: Thermal insulation to prevent personal burns

● Scraper: Scrape off the sticky substance on the wall of the pot

● Homogenizer: Make the composition of raw materials uniform

● Jacket: The full jacket is used for heating or circulating water to achieve the purpose of heating and cooling during operation.

Feature

● The material contacting part is made of SUS316 stainless steel, and half of the cover can be opened, so that the stirring of the material can be observed at any time.

● The stirring paddle can choose one-way or two-way wall scraping according to the material, and the 360° rotation makes the material more evenly stirred.

● The main stirring adopts the frequency conversion speed change device, and the speed can be adjusted arbitrarily from 0-63 rpm.

● The stainless steel electric control cabinet can comprehensively monitor the operation of the equipment, and can display data such as temperature, stirring speed, and emulsification time setting.

● Neat circuit layout, convenient and intuitive operation panel, easy to operate.

Customized

Stainless steel mixing pot is a non-standard customized equipment, which can be customized according to the actual production process needs of customers. The following customizations are for reference:

● If the height of the workshop is insufficient, the stirring motor can be horizontal.

● If the viscosity of the material is high, the false stirring and mixing are more uniform, and the two-way stirring structure can be customized.

● If the production process needs to install the homogenizer on the top.

● If some insoluble raw materials are added in the production process, high-speed dispersion can be added to help the dissolution of raw materials.

● If the viscosity of the material is high, the self-flowing property is not good, or the finished product needs to be transported to a higher storage tank, a transport pump can be installed.The overall platform design of the combined pot can be customized according to actual needs.

Application

Daily chemical industry: detergent, shampoo, shower gel, conditioner, laundry detergent, hand sanitizer, car glass water, dish washing liquid, tire wax, etc.

Technical Parameter

| Capacity | 500L | 1000L | 2000L | 3000 L |

| Pot Temperature | ≤100 ℃ | ≤100 ℃ | ≤100 ℃ | ≤100 ℃ |

| Jacket | Normal Pressure | Normal Pressure | Normal Pressure | Normal Pressure |

| Mixing Speed | 0-63 r/min | 0-63 r/min | 0-63 r/min | 0-63 r/min |

| Homegenizer Speed | 3300 r/min | 3300 r/min | 3300 r/min | 3300 r/min |

| Power | 50-60Hz380V±10%-15% | 50-60Hz380V±10%-15% | 50-60Hz380V±10%-15% | 50-60Hz380V±10%-15% |