Industrial ro plant drinking water purifier machine

Process Flow

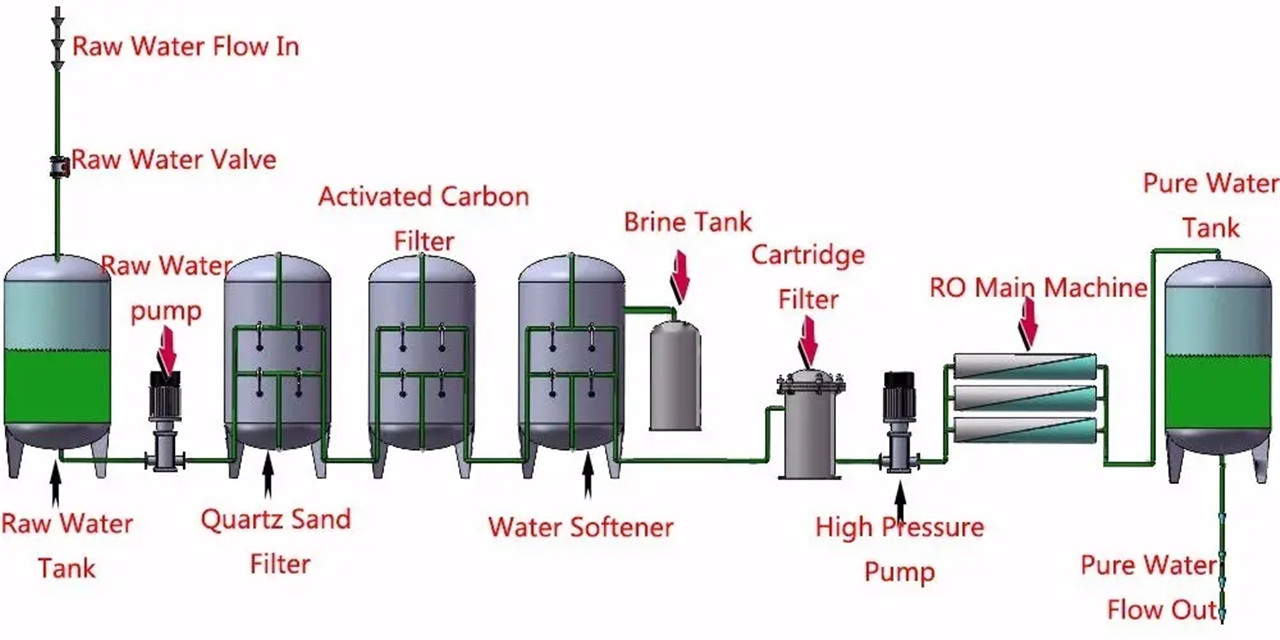

Raw water tank→Raw water booster pump→Quartz sand filter→Activated carbon filter→cartridge Filter→One stage high pressure pump→One stage reverse osmosis system→Pure water tank→Water supply pump→Ultraviolet sterilizer(option) → Use water

Function Description

Raw water tank: It mainly solves the problem of unstable tap water pressure, and reduces the mechanical failure caused by frequent start up of the pump or unstable tap water pressure during operation.

Quartz sand filter: Tap water enters from the upper end of the tank, and flows evenly from the upper end of the filter layer to the lower end through the upper water distributor. After the tap water passes through the filter layer, it is separated from the filter layer through the lower water distributor to form filtered water.

Activated carbon filter: The internal structure is the same as the quartz sand filter. After activated carbon adsorption, the residual chlorine in tap water can generally be reduced to below 0.1mg/l.

Precision filter: The material with particle size larger than 5μm is intercepted to meet the water inlet requirements of reverse osmosis.High-pressure pump: Provides the required power for reverse osmosis operation.

Reverse osmosis system: The reverse osmosis system is the core component of pure water equipment.

Pure water tank: Used to store pure water.

Optional water treatment capacity according to customer's water consumption: 250L, 500L, 1000L, 2000L, 3000L,5000L, etc.

According to different water quality requirements, different levels of water treatment are used to achieve the required water conductivity. (One stage water treatment Water conductivity, Level 1≤10μs/cm, Waste water recovery rate:above 65%)