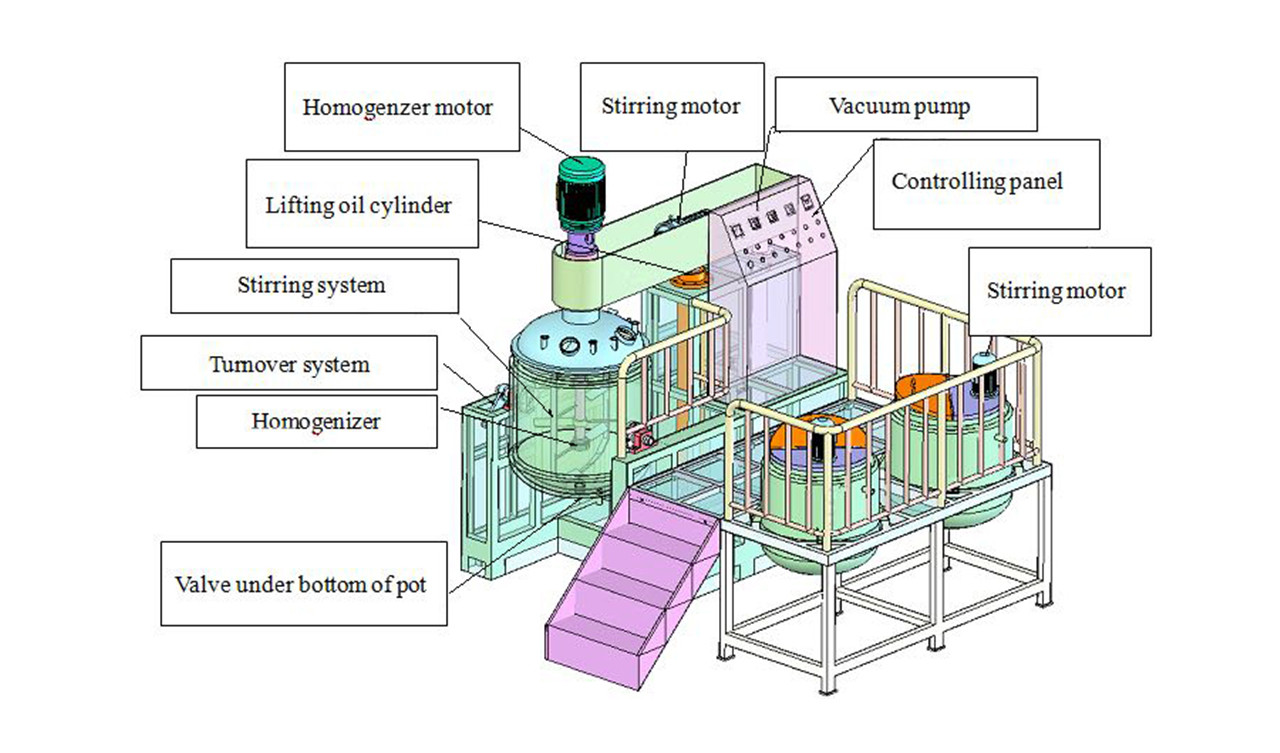

Factory wholesale Cosmetic Making Machine - Vacuum emulsifying mayonnaise homogenizer mixer making machine – YODEE

Factory wholesale Cosmetic Making Machine - Vacuum emulsifying mayonnaise homogenizer mixer making machine – YODEE Detail:

It is cut in the shearing slit and quickly broken into particles of 200nm-2um. Since the emulsification tank is in a vacuum state, the bubbles generated during the stirring process of the material are removed in time. Vacuuming is used to prevent the products from being mixed with air bubbles during the stirring process, so as to ensure that high-quality products with luster, fineness and good ductility can be produced.

Function

● Heating: Steam heating or electric heating.Electric heating is suitable for small-capacity machines, and steam heating is suitable for large-capacity machines. Compared with electric heating, steam heating can heat faster per unit time. It is convenient to add more equipment later to design an automatic control system.

● Stirring: Low-speed stirring 0-63r/min can quickly and evenly mix various raw materials.

● Homogenization: The high shear speed of 0-3300r/min can more efficiently dissolve oil and water to form high-quality products.

● Material suction: In the state of vacuum, liquid raw materials and powder raw materials can be quickly transferred to the container for production through the vacuum suction pipe.

● Vacuum: Make the container form a vacuum sterile environment, adding powder in the vacuum environment can avoid dust pollution and prevent material agglomeration.

Parameter

| Capacity | Homogenizer Motor(KW) | Stirring motor(KW) | Vacuum pump(KW) | water pot stirring(KW) | oil pot stirring(KW) | water pot heating(KW) | oil pot heating(KW) |

| 250L | 5.5 | 2.2 | 1.5 | 0.55 | 0.55 | 12 | 9 |

| 300L | 5.5 | 3 | 3 | 0.75 | 0.75 | 18 | 9 |

| 400L | 7.5 | 4 | 3 | 0.75 | 0.75 | 18 | 9 |

| 500L | 11 | 4 | 3 | 1.1 | 1.1 | 18 | 9 |

| 1000L | 15 | 5.5 | 3.85 | 1.5 | 1.5 | 27 | 18 |

| 2000L | 18.5 | 7.5 | 3.85 | 2.2 | 2.2 | 36 | 27 |

| 3000L | 22 | 11 | 11 | 3 | 3 | ||

| 5000L | 37.5 | 15 | 11 | 5.5 | 5.5 |

Optional System

● Button control/PLC color touch screen

● Cleaning spray ball/CIP system/SIP system

● Piping system (steam pipe / pure water pipe / tap water pipe / cooling water pipe / sewage pipe / air pipe)

● Remote control system

Product detail pictures:

Related Product Guide:

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for Factory wholesale Cosmetic Making Machine - Vacuum emulsifying mayonnaise homogenizer mixer making machine – YODEE , The product will supply to all over the world, such as: Suriname, Botswana, Poland, We are in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!