YODEE was born in Guangzhou, which has the title of world processing factory in 2012. Through the design, manufacturing and sales experience accumulated in the past ten years, we have a complete factory, an excellent team and many very important domestic and foreign partners.

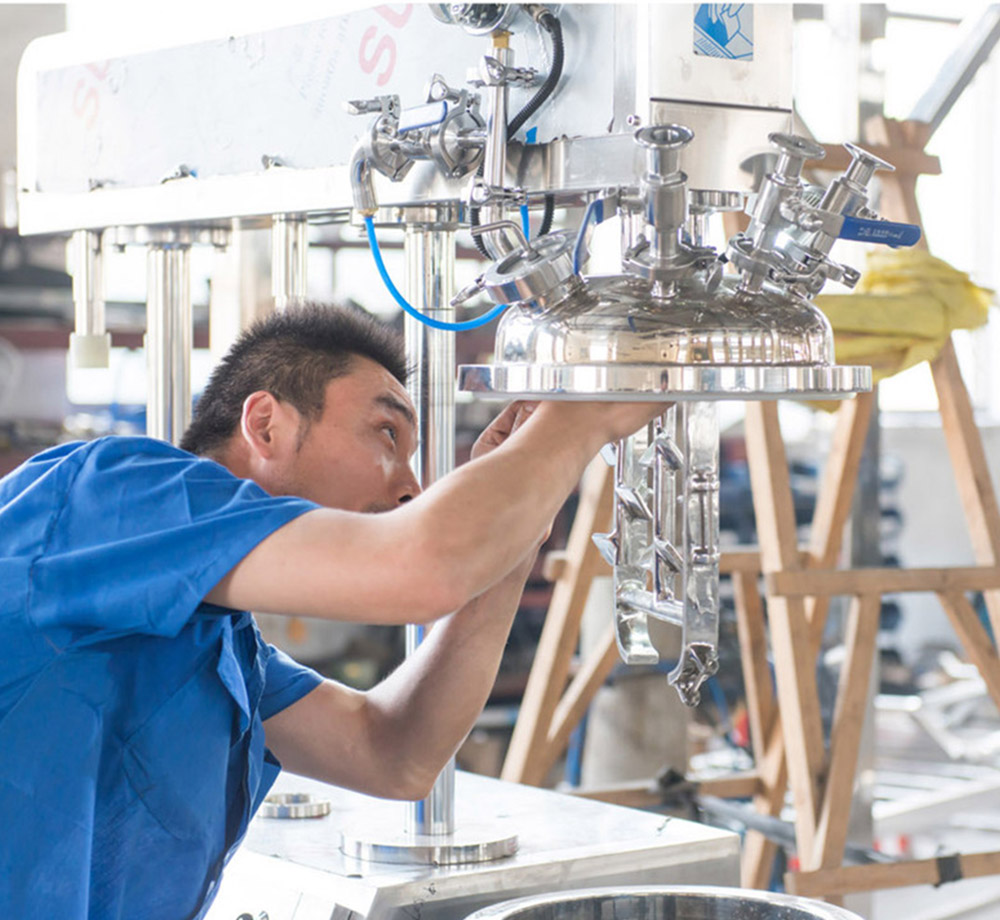

YODEE pays great attention to the quality of the machine and user experience. In the process of pursuing quality, we constantly innovate our technology and strictly control the quality of each part in the selection of materials. Before each machine is delivered to the customer, we need to repeatedly check and test various possibilities to ensure that the machine is at the highest level.

Selection of stainless steel raw materials:

|

Model |

Ni ion(%) |

Corrosion resistance |

Scope Of Application |

|

SUS201 |

3.5-5.5% |

Lower |

Decorative Field, Home |

|

SUS301 |

6%-8% |

Lower |

Auto parts, Dviation |

|

SUS304 |

8%-10.5% |

Middle |

Industry, Food Field |

|

SUS316 |

10%-14% |

High |

Cosmetic, Food, Pharmaceutical Field |

|

SUS316L |

12%-15% |

Very High |

Cosmetic, Food, Pharmaceutical Field |

After completing the selection of materials, YODEE will cut according to the drawings of the machines required by each customer and according to the specifications and sizes, we try to use full-page stainless steel materials instead of spliced stainless steel materials.

The cut stainless steel materials are welded and polished according to the process, and YODEE still has different pursuits for welding technology and polishing requirements. The machine manufacturing is mainly based on shaking welding, and the pipeline is mainly double-sided gas welding. Polishing is 300 mush mirror polishing.

In the field of machining, there are mainly the following welding technologies:

1. Spot welding technology: It can quickly connect two stainless steel parts, but the disadvantage is that it is not strong enough, and there are many gaps between them, and there are perforations and welding slag. Low technical requirements for welders. The aesthetics are relatively low.

2. Sliding welding technology: the welding surface is relatively dense, relatively firm, the gap is better, the perforation is relatively low, there is a certain welding slag, and the aesthetics is medium.

3. Shaking welding technology: the welding surfaces between each other can be perfectly matched, very reliable, no gap, no perforation, no welding slag, and high aesthetics.

4. Double-sided gas-filled welding technology: use carbon dioxide gas to protect the welding surface, with a small molten pool, a more suitable welding surface, beautiful appearance, no welding slag, no analysis, and good welding quality.

Polishing process:

1. Preliminarily rough grinding and polishing the product, and use sand abrasive to grind the workpiece with rough surface to remove the macro uneven surface

2. Next, further polish on the basis of rough grinding to remove rough grinding marks. After this process, the surface of the workpiece is gradually smooth and bright.

3. Finally, carry out the next step of fine grinding and polishing, so that the workpiece can achieve the most ideal brightness and aesthetics.

YODEE's partner assembles all the parts, and makes preliminary adjustments and inspections.

All YODEE workpieces are assembled to form a complete machine, and the quality inspection engineer conducts a 24-hour pre-delivery test on the machine in the factory.