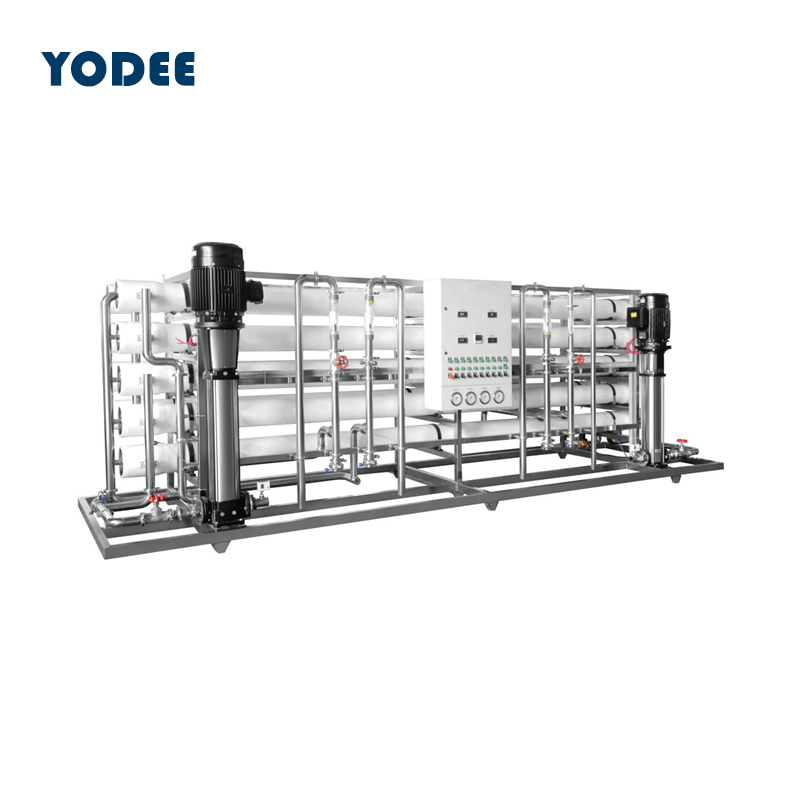

10T large plant reverse osmosis water treatment plant with EDI

Function

YODEE's reverse osmosis water treatment machine is mainly designed for the conductivity of water, and different conductivity is different for different industries. According to the different needs of each water consumption, water quality (metal ion content in water), electrical conductivity, etc., different reverse osmosis machines are designed and manufactured to be suitable for different scenarios.

To judge the local water quality, the most important thing is to test the conductivity and metal ions in the water. The conductivity of the water has a certain relationship with the amount of inorganic acids, alkalis and salts it contains. When their concentration is low, the conductivity increases with the concentration, so this indicator is often used to infer the total concentration of ions or the salt content in water. Different types of water have different conductivity. The conductivity of fresh distilled water is 0.2-2μS/cm, but after a period of time, it will increase to 2-4μS/cm due to the absorption of CO2; the conductivity of ultrapure water is less than 0.10/μS/cm; the conductivity of natural water is more Between 50-500μS/cm, mineralized water can reach 500-1000μS/cm; the conductivity of industrial wastewater containing acid, alkali and salt often exceeds 10,000μS/cm; the conductivity of seawater is about 30,000μS/cm. Conductivity is an important indicator to measure the purity of pure water, which reflects the purity of pure water and the control of the production process. The national standard stipulates that the conductivity of pure water shall not be higher than 10μS/cm.

According to different water quality, the corresponding machines are divided into primary reverse osmosis water treatment, secondary water treatment, EDI water treatment, and the maximum value of pure water conductivity can be reached:

Parameter

| Capacity | Water production(LPH) | One Stage RO water treatment (TDS:μS/cm) | Two Stage RO water treatment (TDS:μS/cm) | EDI+ RO water treatment (TDS:μS/cm)(TDS:μS/cm) |

| 500L | 500L | ≤10μS/cm | ≤3μS/cm | 0-1μS/cm |

| 1000L | 1000L | ≤10μS/cm | ≤3μS/cm | 0-1μS/cm |

| 2000L | 2000L | ≤10μS/cm | ≤3μS/cm | 0-1μS/cm |

| 3000L | 3000L | ≤10μS/cm | ≤3μS/cm | 0-1μS/cm |

| 4000L | 4000L | ≤10μS/cm | ≤3μS/cm | 0-1μS/cm |

| 5000L | 5000L | ≤10μS/cm | ≤3μS/cm | 0-1μS/cm |

| 10000L | 10000L | ≤10μS/cm | ≤3μS/cm | 0-1μS/cm |

Future

1. Automatically prepare pure water system

2. Adopt imported brand Dow reverse osmosis membrane and Korean reverse osmosis Shihan membrane

3. The whole machine is made of SUS304 stainless steel, which is beautiful and beautiful.

4. The pipeline system adopts CO2 gas-filled welding, no welding slag inside and outside, and conforms to GMP and CE international standards.

5. The PLC touch screen conforms to the 4.0 industrial standard.

6. With automatic warning function, each part can be displayed on the color touch screen.